We put a lot of effort and care into our work, and we promise you a quality installation. Here are some examples of systems we install.

'After' and 'Before' photographs of the installation of a Lennox G61MPV (two-stage furnace with variable speed blower). We took out the old, archaic furnace, installing the new furnace. The customer receives many benefits: New, reliable equipment with a factory warranty, increased home value, reduced operating costs, better, more even comfort, quieter operation, and better air flow to name a few.

Above is an Luxaire LP9C furnace. It is 98% efficient, and has a modulating burner and variable speed blower motor. Because of its variable speed blower, this furnace is extremely quiet starting and stopping. And because of its modulating burner, it puts out just the right amount of heat to keep your home at the temperature you want. The result is extremely even comfort throughout your home. Also, at 98% efficiency, you are sure to save 18% on operating costs when compared to a modern 80% efficient draft assisted gas furnace. And if you have a natural draft furnace, you will save 21% or much more, depending on the old furnace's specific design and control system.

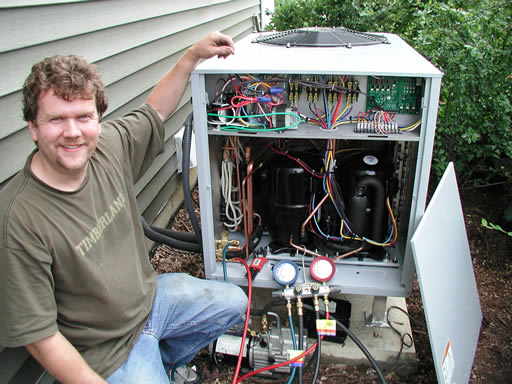

Hallowell Acadia combined heating and cooling system. This system received the 2008 AHR (Air Conditioning, Heating, and Refrigeration) Expo Innovation Award in the Heating category. Its innovative technology includes a booster compressor in series with a two-stage compressor. This unique configuration allows it to extract heat from the outside air even in extreme cold weather. The unit provides near geothermal efficiencies without the expense of installing a geothermal ground loop, and it utilizes environmentally friendly R-410a refrigerant. "The AHR Expo Innovation Award Competition is jointly sponsored by Show Organizers (International Exposition Company), the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), and the Air-Conditioning, Heating, and Refrigeration Institute (AHRI)." Ref. http://www.ahrexpo.com/innovation/

This is a high efficiency (93% AFUE) Luxaire natural gas sealed combustion horizontal furnace pictured without its doors on. The installation was completed after precise calculation of heating and air conditioning loads and equipment selection based on those loads. The challenge was to replace an existing upright furnace taking up valuable floor space with a horizontal furnace fit snuggly into this crawl space area where it would be out of the way and heat and cool the existing home as well as a new addition. An Ultravation media air cleaner (partially obscured by the large return air grill) can be seen on the left end, and a GeneralAire 1042-DME humidifier can be seen on the right end. Just to the left of the large post you can see the evaporator coil for the air conditioning portion of the system. A 3 ton nominal capacity Luxaire 13 SEER condensing unit (not pictured) sits just outside the back wall. The condenser is connected to the evaporator coil via the refrigeration line set. To minimize noise and vibration, 1) the furnace floats on vibration isolating pads placed on top of concrete blocks, 2) the furnace is isolated from the air distribution system's duct work via flexible duct connectors, and 3) the supply and return air plenums are lined with sound deadening duct lining material. Custom large radius sheet metal elbows minimize resistance to air flow, with the entire air distribution system designed to allow for proper air distribution throughout the home (based on individual room loads). Registers and grills were sized and positioned to maximize comfort while minimizing noise and drafts. A condensate pump sits below the furnace, pumping away condensate from the furnace and air conditioner, as well as waste water from the humidifier.

This is WaterFurnace Synergy 3 geothermal heat pump system. This is a 4 ton nominal capacity unit with on demand water heating. Behind the heat pump (not pictured) is a storage tank which stores water heated by the heat pump. That heated water is circulated through tubing in the basement floor (pictured at right prior to pouring of the basement floor slab) to provide radiant heat to the basement during the heating season. The photo of the heat pump was taken prior to connection of the ground loop and electricity. The unit is shown sitting on a vibration absorbing base and with flexible duct connectors which limit transmission of noise to the occupied space. All duct work was designed to match the performance of the unit's blower. The air distribution system is zoned so that the basement receives supply air flow only during the air conditioning season (since it is heated by the radiant floor and does not need supply air flow during the heating season). Also included in the installation are a humidifier (top center) and energy recovery ventilator (top right). The energy recovery ventilator brings in fresh air from outside while exhausting stale inside air; exhaust and supply air pass through a heat exchanger (recovering sensible and latent heat in the winter and preventing excessive sensible and latent heat intake in summer).

This is a Luxaire GM8S 80% AFUE furnace (100,000 Btu/Hr. input, 80,000 Btu/hr. output), a really wonderful furnace. Also included in the installation is an Ultravation Progressive Media Air Cleaner; the air cleaner provides MERV 11 filtration with a MERV 8 pressure drop characteristic.

GeoComfort geothermal heat pump. This is a 5 ton nominal capacity two-stage unit. This photo was taken prior to connection of the ground loop and electricity. Unit is shown sitting on a vibration absorbing base and with flexible duct connectors which limit transmission of noise to the occupied space. All duct work was designed to match the performance of the unit's blower. This particular unit has a variable speed blower and is charged with environmentally friendly R-410a refrigerant. Supplemental / backup electric strip heat included is internally installed.

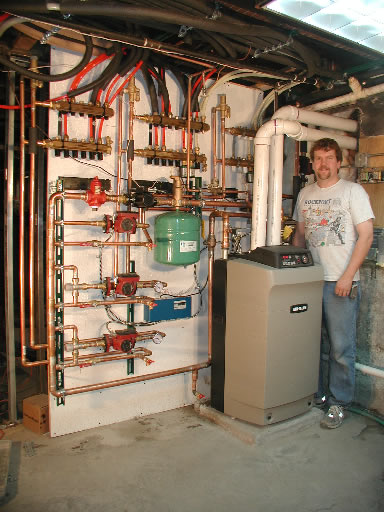

Bob with multi-temperature radiant panel heating system. System is heated by a Weil-McLain Ultra 105 high efficiency boiler. Boiler is also used to heat domestic hot water (tank not shown). Photo was taken after main piping was installed, but prior to completion.

Bob again with same system. Vent piping for combustion air and exhaust is connected. Here the system is almost complete, though a few radiant panels still need to be connected to their manifolds, and some control wiring is not done.

High efficiency heating and air conditioning installation. Installation includes a Luxaire two-stage furnace, 12 SEER Luxaire air conditioner, Ultravation media-type air cleaner, and General humidifier. Evaporator coil for air conditioner is shown sitting on top of furnace. Condensing unit and vent pipe terminations are shown in the next photo.

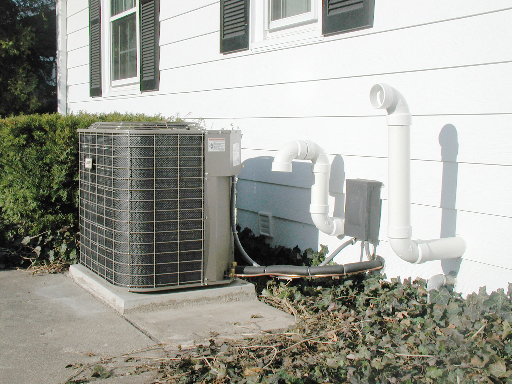

This picture shows the other half of the system above. The condenser was

mounted on a concrete base. Since the installation was a retrofit, the existing

electrical hardware was reused for the new condensing unit, though it is not

as pretty as if new electric was run. We were also somewhat limited in our

choice of placement of the exhaust and combustion air intake pipes for the

furnace, though the installation turned out nicely.